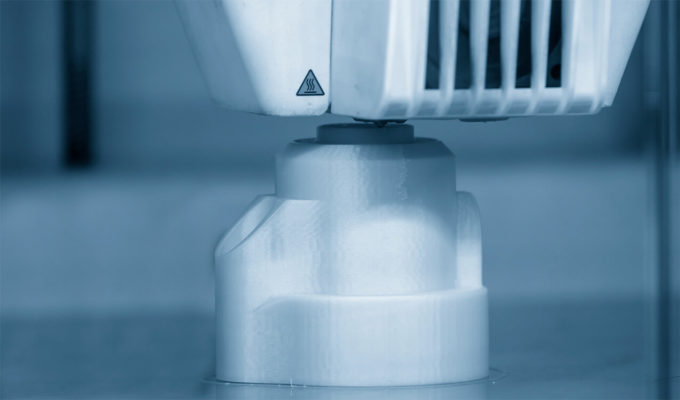

3D printing

3D printing, also known as additive manufacturing, is a manufacturing process in which objects are built up layer by layer based on digital design data. The material is only applied where it is needed for the component.

Operating principle

Usually, a CAD model is divided into thin, horizontal layers. Depending on the process (e.g. FDM, SLS, metal 3D printing) is applied or solidified in precisely these layers. The object is thus created gradually from bottom to top.

Typical applications

- Prototyping: rapid production of sample components for checking the fit or design.

- Small series production: manufacturing small quantities for which the purchase of expensive moulds or tools is not worthwhile.

- Spare parts and custom-made products: individual adaptations or rare components can be manufactured in a targeted manner.

Advantages

- High degree of design freedom: Complex geometries are possible without significant additional effort.

- Resource-efficient: Usually less material waste than with subtractive methods.

- Short development cycles: Design changes can be implemented quickly.

- No costs for a mold necessary

Disadvantages

- Printing time and space: Producing larger quantities or larger dimensions can be time-consuming.

- Choice of materials and costs: Some materials are more expensive than conventional raw materials, and not all materials are available in every technology.